Asparagus are very interesting plants! They are unique from other vegetables in all aspects, including growing, harvesting and packing.

Table of Contents

How Does Asparagus Grow?

Asparagus plants grow more like fruit trees, instead of like most other vegetables. Let me explain! When an asparagus plant establishes itself, it forms a crown underground. The roots grow from the crown, which is also where the buds form. Buds are crucial to the success of the plant since each bud results in one individual asparagus spear. Over time, the crown grows larger and larger because every time a new bud is formed, only one asparagus spear will form from that.

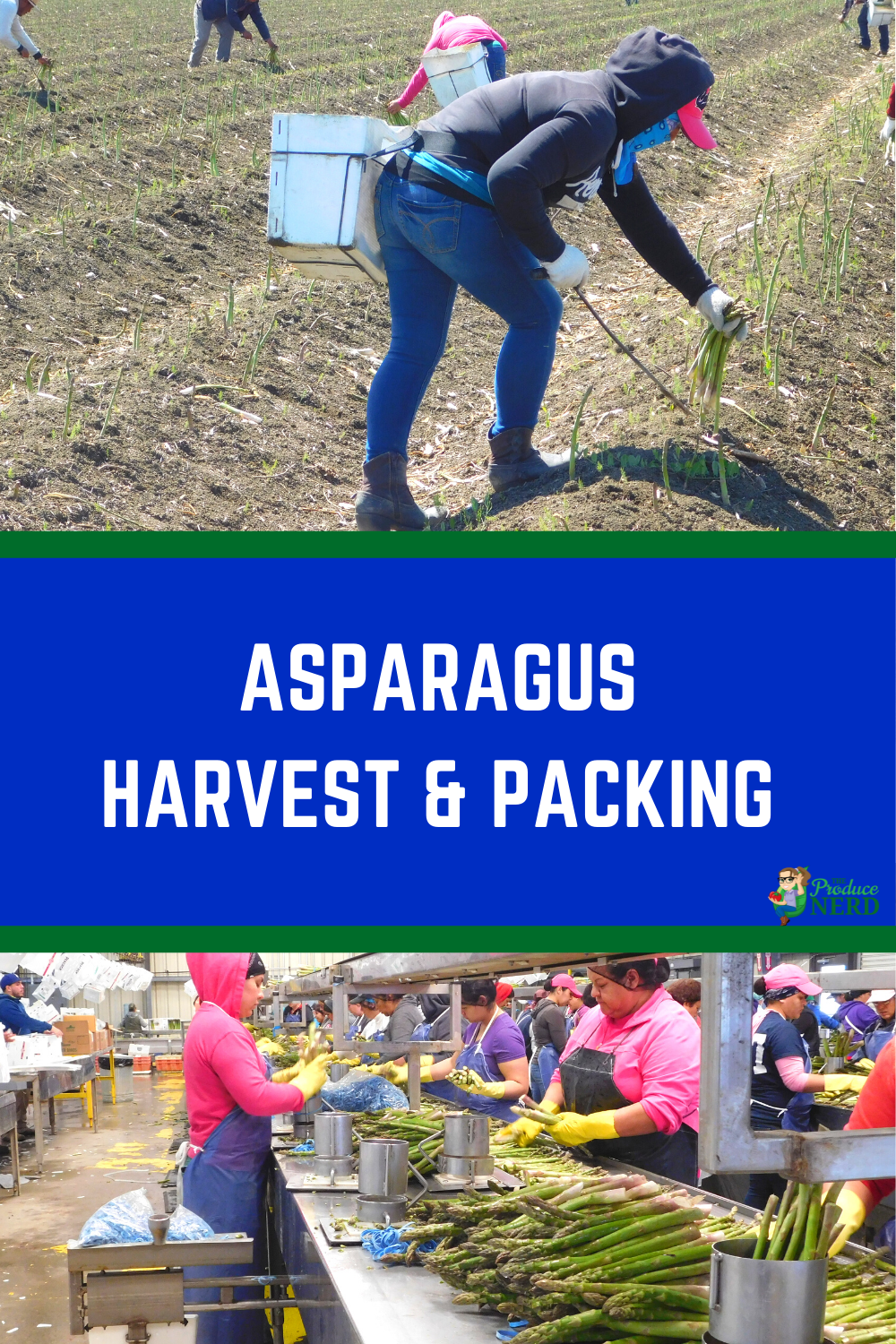

Asparagus Harvesting & Packing

To take a glimpse into the world of asparagus harvest and packing, see the detailed video below.

Asparagus Harvesting

Is all asparagus ready for harvest at the same time?

Since asparagus spears grow at random, an entire field is not ready for harvest at one time. The harvesters have to walk the fields and determine which asparagus meet the quality requirements (e.g., maturity stage, height) and are ready for harvest. The asparagus that are not yet ready for harvest will be left in the field, and the harvesters will return days later once those spears are ready for harvest.

How is Asparagus Harvested?

The harvesting process consists of the workers walking through the fields with an asparagus knife and when the asparagus spear is ready for harvest, the workers slide the asparagus knife underneath the soil mound to make the cut. They do this because if they were to make the cut above the soil, the plants acts as though it will rejuvenate another spear from that same bud and continues utilizing plant resources to attempt to make that happen. However, as we learned previously, no two spears arise from the same bud.

Once the spears are harvested, the workers place them into the harvesting buckets that they wear over their shoulders. Once those fill up, the harvesters empty them out on the soil mounds and form piles of asparagus. Another portion of the harvest crew goes through the field and picks up the asparagus and places them into bins, which are then transported to the packinghouse.

Asparagus Packing

The asparagus arrive at the packinghouse in the field packed bins. From there, they are either ran through a manual packing line or an automated packing line. The goal of being ran through either packing line is to result in rinsed asparagus that is sorted into bunches based on the diameter of the asparagus spear. When the bunches are packed into boxes, they are packed by the size of the spear. You have probably never seen asparagus come in boxes like these, but they are just filled with the asparagus bunches that you buy at the grocery store.

- Box Formation – The boxes are formed on site. They are then transported overhead to both the manual and automated packing lines for easy access to the packers.

- Bin Removal – The asparagus is manually removed from the field packed bins and placed on the packing line.

- Initial Trim – The asparagus go through an initial trimming step to make them a more uniform length.

- Wash Step – After being trimmed, the asparagus go through a single-pass rinse step using sanitized water.

- Sorting – In the manual packing line, the workers sort out the individual asparagus spears based on their diameter.

In the automated packing line, a machine does this. Each spear is placed into its own cup (workers are needed to make sure there is only one spear per cup for measuring purposes), and goes through an optical sorter that sorts the spears based on diameter and drops them into collecting containers.

- Packing into Bunches – In the manual packing line, workers take the sorted asparagus and create bunches based on spear diameter. When doing this, they use a tool that helps shape the bunch and easily place the rubber bands around them. They are then transported overhead and pass through a second trimming step to make them more uniform in length.

In the automated packing line, workers move the sorted asparagus from the collecting containers into separate containers on the packing line, so that they can be transported to have the rubber bands mechanically placed around the bunches.

- Quality Assurance – Random bunches are selected and weighed to make sure they meet the customer weight specifications.

- Packing into Boxes – In both scenarios, workers pack the bunches into boxes based on the diameter of the asparagus spears.

- Labeling – Once full, each of the boxes are labeled to indicate the packing date.

- Quality Assurance – The final quality assurance step consists of weighing the packed boxes. This step is performed to verify that the box weight meets the customer specifications.

- Hydrocooler – The packed asparagus boxes are closed and ran through a hydrocooler. The hydrocooler works to remove the field heat and to quickly cool down the asparagus.

- Cold Storage – The hydrocooled boxes arrive at the cooler, where they are palletized by box size and shape. They are stored in the cooler until transport.

Food Safety Considerations

For an asparagus harvesting and packing operation, some of the main food safety concerns are:

- Sanitation of the harvesting containers and bins – Cleaning and sanitizing of the harvesting containers and bins needs to occur on a regular and frequent basis.

- Sanitation of the harvesting tools – Cleaning and sanitizing of the harvesting tools needs to take place on a a regular and frequent basis, performed by the company, and there needs to be some sort of dip/storage for the tools when the workers are on break.

- Testing and changing of the wash water – The asparagus is exposed to water during the packing process (the single-pass wash step) and after packing when the cartons are hydrocooled. There needs to be a water testing policy in place and implemented.

- Glove policy – There needs to be rules for which gloves can be worn, and if they are disposable, when they should be changed, or if they are reusable, how often and how they will be cleaned. If reusable gloves are used, they need to be able to be cleaned and that cleaning needs to be handled by the company and not the individual worker.

There are many more items to be taken into consideration, but this is just a brief list to get you thinking about it!

Postharvest Considerations

The two main postharvest factors to consider with asparagus are cooling and hydration. Asparagus needs to be cooled down to between 0-2°C/32-35.6°F (according to the UC Davis Postharvest Center) to have an optimum shelf-life. To maintain sufficient hydration, they are commonly shipped with wet pads to keep the cut ends from drying out, and you will even see them with water on displays at some grocery stores. They are similar to cut flowers in that the cut ends can easily dry out and then they age quicker.

Frequently Asked Questions

Is asparagus still grown in California?

Yes, but very little compared to what asparagus farming in California used to look like. It is estimated that there is approximately 500-600 acres of asparagus being grown, when there used to be 60,000 acres. California growers find it difficult to compete with the international markets, since the daily wage for workers in California is significantly higher than those in other countries.

When is asparagus harvesting season in California?

Between the three regions where asparagus used to be commonly grown throughout California, the harvesting period lasted between January to June.

When is the asparagus harvesting season in Mexico?

Asparagus can be harvested year-round throughout the different regions in Mexico, which is another advantage it has over California production.

What tool is used to harvest asparagus?

Asparagus harvesting tools are specific to asparagus, and are often referred to as asparagus knives. They have a flat portion at the end that they use to dig into the soil to cut the asparagus under the soil line. The one below is similar to what you saw in the video above.

Featured Grower Information

I would like to send a big thank you to JMB Produce for the tour and for allowing the gathered content to be shared. JMB Produce is an asparagus shipper that markets asparagus year-round for growers and packers throughout California and Mexico. The specific grower and packing house featured in this post are located in Firebaugh, California, but JMB Produce has growers throughout California, Mexico and Peru.

If you enjoyed this post, please share it!

Some other posts that might be of interest:

Thank you for the informative video and story board. Best I have found on Youtube

Thank you, Mateaus! That’s great to hear!

How do you calculate the size of the packing facility in order to sufice harvest ? Is there a ratio ?

Also, Is there a machine that can properly harvest and eliminate the labor /human hours ?

Pingback: How to Select and Store Asparagus - The Produce Nerd