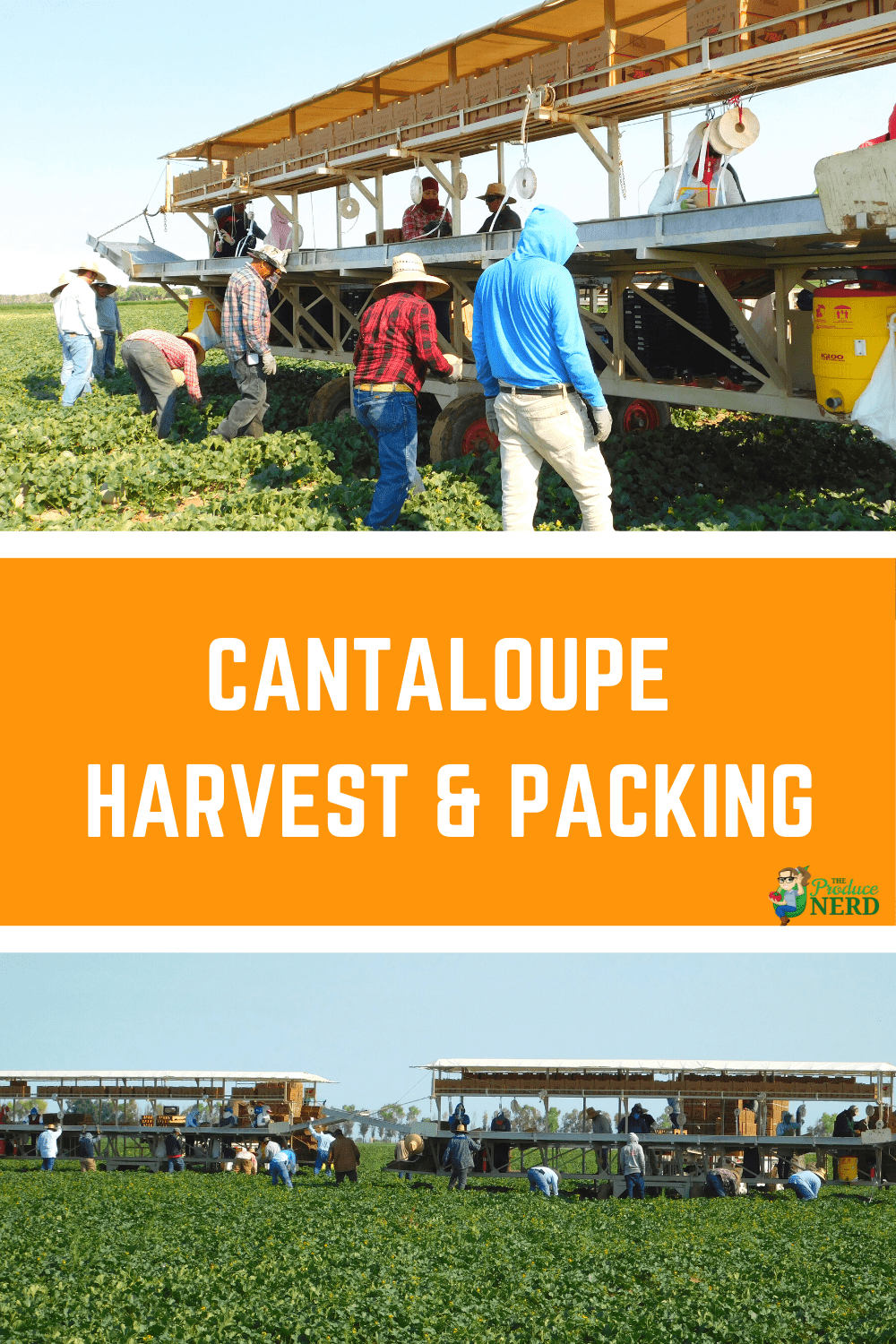

Learning more about cantaloupes, the different types that are grown and how they are harvested and packed is so interesting (and tasty)! I recently visited Westside Produce, located in Firebaugh, California to get a glimpse of the cantaloupe harvesting and packing process that is common for California production.

During my visit, it was the start of the season and there were already three cantaloupe harvest crews moving through the field. Westside Produce employs its own harvest crews and typically has 20 crews during the harvest season. Westside Produce also participates in the “transition“ that is common with leafy green growers. During the winter months, they have growers growing for them in the Yuma, Arizona region. This way, they are able to provide cantaloupes for at least 6 months out of the year.

Table of Contents

Where do Cantaloupes Grow in California?

The two main growing regions in California are in the San Joaquin Valley (in the central part of the state) and the Imperial Valley (the southeastern part of the state). According to the California Cantaloupe Advisory Board, California cantaloupe growers produce 75% of the cantaloupes grown in the United States.

When describing the transition between growing regions above, Yuma, AZ is located in the same region as the Imperial Valley, just in the adjacent state! For the crops that transition between the different growing areas, the Imperial Valley of California and Yuma, AZ are one in the same.

When is the California Cantaloupe Season?

Between the two California growing regions, there is a steady stream of cantaloupes from April to December. According to the California Cantaloupe Advisory Board, the season begins in the Imperial Valley and runs from April to July, and then again from October to December. The cantaloupes grown in the San Joaquin Valley are harvested between June and October.

How do Cantaloupes Grow?

Cantaloupes plants are annual plants, meaning that they complete their life cycle during one planting. The actual plants are vines that normally trail along the ground in large growing operations. On average, it takes approximately 75 days from planting to harvest, so there is continuous planting throughout the season.

To give you an idea of the growing process, here are some examples of the progression of the cantaloupe plants.

How are Cantaloupes Harvested?

Cantaloupes are harvested by hand, without the use of any harvesting tools. Since cantaloupes do not get sweeter after harvest, the harvesters need to be trained to harvest ripe cantaloupes. As the harvest crew is looking for ripe cantaloupes, they only harvest the ripe cantaloupes and leave the rest for further ‘passes’ through the field. This is a very tedious task, since there are three main types of cantaloupes that are grown and harvested and they all have a different indicators for when they are ready to be harvested.

For the traditional Western Shipper cultivars, there can be up to 10 passes through the field. For the extended shelf-life, they average around 5 passes per field, while the long shelf-life cantaloupes can be harvested in 2-3 passes or, in some cases, all at one time.

Cantaloupe Harvest

During harvest, there is a harvest crew in the field that moves along with the harvesting rig. There are also other crew members located on the harvesting rig.

The harvest crew working the field portion are checking to see whether the fruit is ripe. Depending on the type of cantaloupe, it is up to the harvesters to check the ‘slip,’ the exterior netting and the firmness of the cantaloupe.

They harvest the melons simply by removing the vine from the melon. No tools are needed because if the melons are ripe, they easily separate from the vine when nudged.

Cantaloupe Packing

After harvest, they place the cantaloupes on the packing table, where the workers label the fruit and pack them into boxes. The packers have to sort the melons by size based on how many will fit into a box, and pack accordingly. For example, if there are larger melons and only six will fit into a box, they need to have a box designated for those melons, as well as other boxes to accommodate the other sized fruit that arrives on the packing table.

Once the boxes have been filled, they are closed, labeled, and sent to the adjacent trailer to be palletized. There is a labeler that catches the boxes as they pass through to the adjacent trailer for trace back purposes.

Cantaloupe Cooling

After the adjacent trailer has been filled, it is taken to the nearby cooler. The pallets of harvested boxes are forced air cooled (picture on the left) upon arrival and placed onto storage shelves (picture on the right). This was the first time I have seen one of these types of storage shelves and I was really impressed. The pallets are inserted on a gravitational slope, so once they enter the shelving unit, gravity moves them downward to the other side of the storage shelves. By using this, the operation is able to apply first in, first out (FIFO) principles, so that you are able to get the freshest product.

Cantaloupe Harvest, Packing & Cooling Video

See the video below for a full behind the scenes view of the cantaloupe harvesting, packing and cooling processes.

Food Safety Considerations

For a cantaloupe harvesting and packing operation, some of the main food safety concerns are:

- Worker hygiene – Since the harvesters touch every melon they harvest and the packers pack them individually, there is a lot of handling taking place. Whether they are using their bare hands or gloves, there needs to be a hygiene policy in place to ensure that hand washing occurs every time before they return to work, and if they are using gloves, that they are clean and/or switched out regularly.

- Cleaning and Sanitation of the harvesting rig – Every piece of harvested product touches the conveyor line between being harvested and packed, so it needs to be cleaned and sanitized to prevent any potential cross-contamination issues to the product.

There are many more items to be taken into consideration, but this is just a brief list to get you thinking about it! There are also questions that arise (due to prior food safety issues with cantaloupes at other operations) about any wash water used during the harvesting and packing process, and there is no water used postharvest at this operation, and it is also not a typical practice for melons grown in California.

Featured Grower Information

I would like to thank Westside Produce for the tour and for allowing the gathered content to be shared. This company is a cantaloupe shipper that is involved in the day-to-day operations of the cantaloupe and honeydew growers that supply to them. Not only was I lucky enough to get to sample some cantaloupe in the field, but I also got to take some home with me. No joke, that was the best cantaloupe I have ever tasted, so you know they are doing something right!

If you enjoyed this post, you might also like:

I’m doing research on a cantaloupe listeria outbreak in Colorado in 2011. The cantaloupes were not cleaned properly and the result was the death of 33 people and sickening of over a170 other people. The farm went bankrupt. Where is the cleaning step in the process here? It was not included in the video that I saw. I’d like to know more. Thanks!