Radishes are considered a specialty crop, but by this point, it is pretty likely that most adults reading this have tried one. If you think you are not a fan, you better start checking the ingredients in the salads you order out! This is a pretty exciting post, as you will get to see both radish harvesting and processing, and get a perspective from how two different companies work.

Table of Contents

Babé Farms in Santa Maria, California grows multiple different types of radishes, but the French Breakfast radishes were the ones being harvested during my visit.

In addition to the French Breakfast radishes, I also got to see Purple Ninja radishes for the first time! From the outside, they almost look like purple carrots. However, when you cut them open, they are a sight to see! They are also a bit spicier tasting than the other radishes.

Although the different radishes look and taste a bit different from each other, the growing and harvesting processes are the same.

Radish Harvest

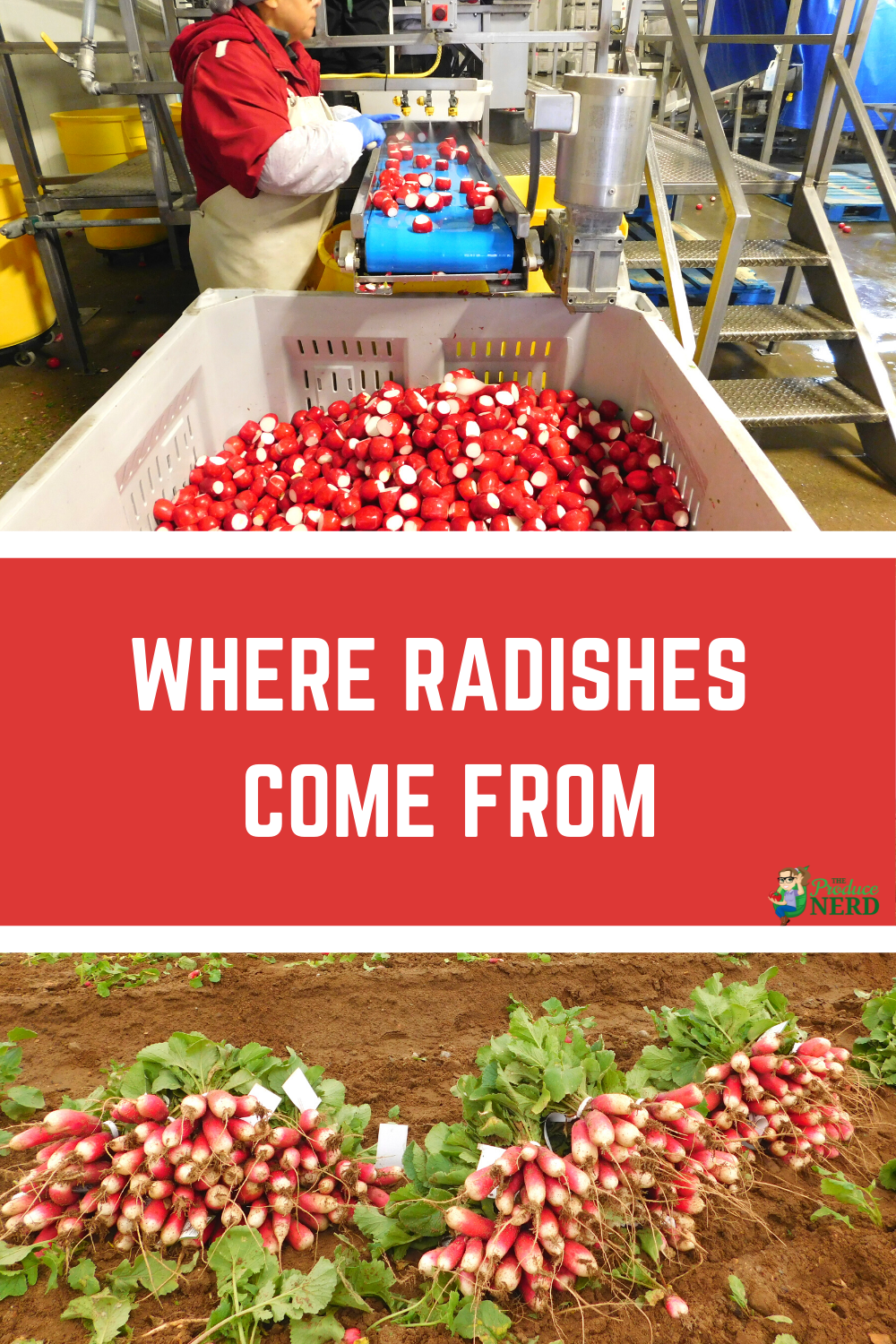

Radishes are root vegetables that grow underground. During radish harvest, the workers hand harvest the radishes and remove them from beneath the soil line. The workers group the harvested radishes into bunches, place a tie around them and then place them into a pile. There is then a designated worker that comes through with RPCs (reusable plastic containers) to collect all of the harvested bunches. These are then placed on a truck and taken to a nearby on-site packing area, where they are rinsed with sanitized water to remove the excess soil and packed into boxes.

The harvested radishes can either be washed, packed and sold in bunches, as is done with the radishes from Babé Farms, or they can go on to further processing, as is shown below.

Radish Harvesting Video

Check out the video below to see the full radish harvesting process!

Radish Processing

At Sabór Farms, a grower and processor based out of Salinas, California, their processed radish product results in trimmed (also known as topped and tailed) radishes. The process to create those “trimmed” radishes is as follows:

- Bin Dump – The harvested radishes that are brought in from the field, and are dumped onto a conveyor line.

- Sort and Wash – The radishes are sorted, rinsed with sanitized water, and the culls are removed as they pass through the conveyor line.

- Conveyor – The rinsed radishes are then carried to a separate room on the conveyor line for the processing step.

- Processing – Each worker is assigned to a line and is responsible for placing radishes in the individual cups. The radishes are then mechanically sliced, or topped and tailed, at the top and bottom portions of the radishes are removed.

- Quality Assurance – The radishes pass through a final sanitized rinse step. They then go to the Quality Assurance worker who removes any parts that the machinery might have missed.

- Packaging – The completed product is then bagged, where the bags are then sealed and palletized.

Radish Processing Video

You can see additional details from the radish processing step in the video below.

Featured Grower Information

I would like to thank Babé Farms and Sabór Farms for the tours and for allowing the gathered content to be shared. Babé Farms is a specialty vegetable grower, centrally located in Santa Maria, California, that specializes in baby vegetables. While, Sabór Farms is a vegetable grower located in Salinas, California.

You can see more harvesting and packing operations from both company at the following links:

- Babé Farms – Lettuce harvesting machine, Kale, Romaine, Carrots, Blonde Frisée, Spring Mix

- Sabór Farms – Escarole, Endive, Leeks, Bok Choy

If you enjoyed this post, you might also like: